How to cope with high computing power demand? Liquid cooling technology helps data center upgrade (previous issue)

With the rapid development of mobile Internet, cloud computing and big data, as well as the advancement of national strategies such as "Digital China", the amount of data generated by the whole society continues to grow, driving the construction of data centers to accelerate. At the same time, the rise of artificial intelligence and 5G has also driven a significant increase in computing power demand, and the heat dissipation pressure has increased accordingly.

Air cooling is still the mainstream cooling method for data centers. It has advantages such as low construction cost and mature technology. However, its cooling efficiency is far inferior to that of liquid cooling. Experiments have confirmed that the PUE (power usage effectiveness) of air-cooled data centers is usually between 1.3 and 1.5, while the PUE of liquid cooling technology can be reduced to below 1.05.

As chip performance continues to improve, the power consumption of a single chip may exceed 1kW, and that of a single cabinet may exceed 150kW. Air cooling will become increasingly difficult to cope with the ever-expanding cooling needs, while liquid cooling will become a better choice for the next generation of data centers due to its higher cooling capacity.

1. Classification of liquid cooling technology

Liquid cooling technology can be divided into the following two categories depending on whether the heat-generating device is in direct contact with the cooling medium:

① Direct contact liquid cooling: The coolant is in direct contact with the chip, including single-phase immersion liquid cooling, phase change full immersion liquid cooling (two-phase immersion liquid cooling) and spray liquid cooling;

② Indirect contact liquid cooling: The coolant takes away the heat indirectly through the cold plate and does not directly contact the chip, including single-phase cold plate liquid cooling and phase change cold plate liquid cooling.

As the technology of cold plate liquid cooling is relatively mature and easy to transform, it has now become the mainstream solution in the market, helping data centers to upgrade.

2. The principle of cold plate liquid cooling technology

Cold plate liquid cooling technology: The heat of heat-generating components such as chips is indirectly transferred to the cooling liquid enclosed in the circulation pipeline through the cold plate. The coolant takes away the heat and transfers it to the primary side circuit, where it is cooled by the cooling system and finally the heat is discharged from the system.

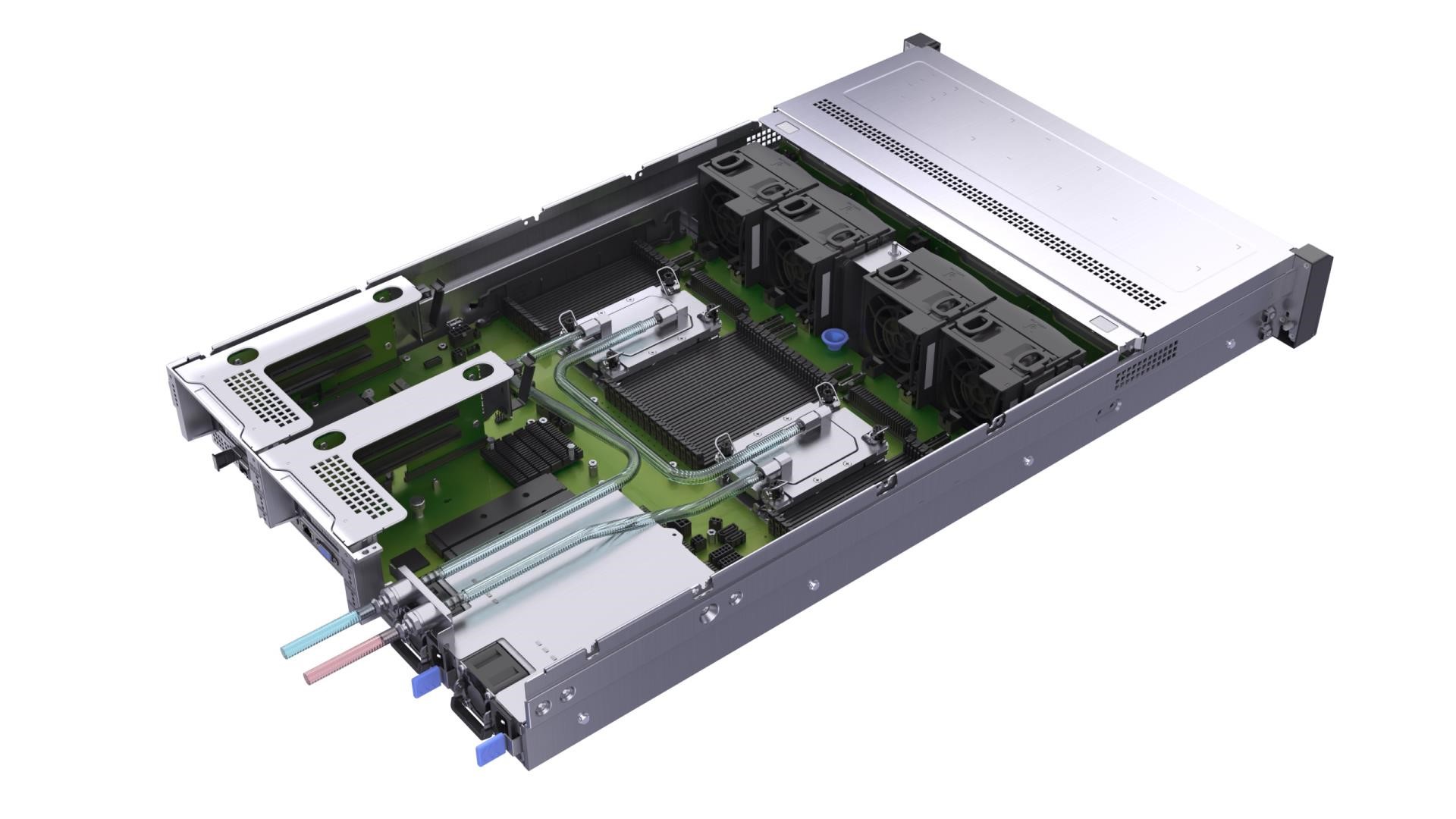

▲ Cold plate server

Cold plate liquid cooling technology uses coolant as a medium for heat transfer, transferring heat from the heat source to the remote end before cooling. The coolant has a stronger thermal conductivity than air, and can absorb and transfer heat faster, effectively reducing noise and dust pollution in the computing center and optimizing the overall environment of the computing center.

3. Detailed explanation of cold plate liquid cooling system design

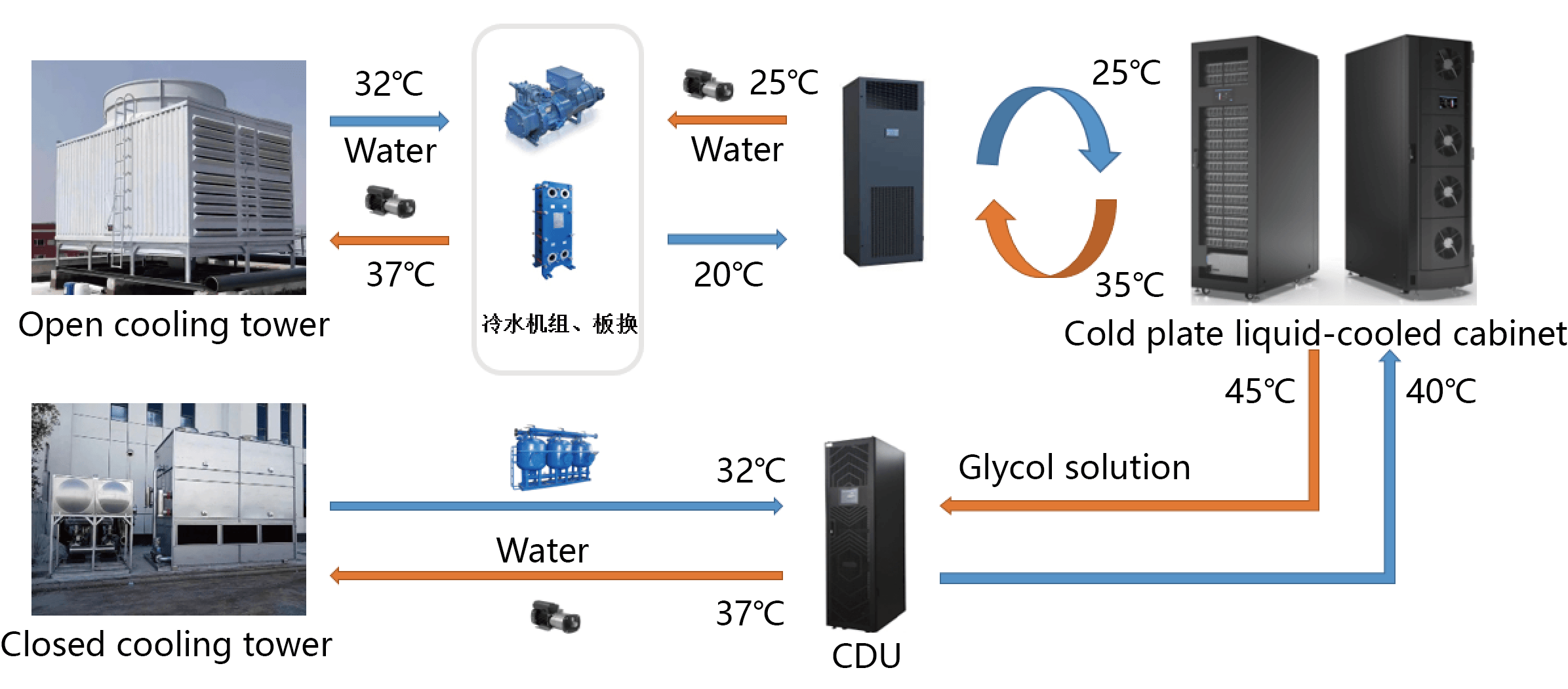

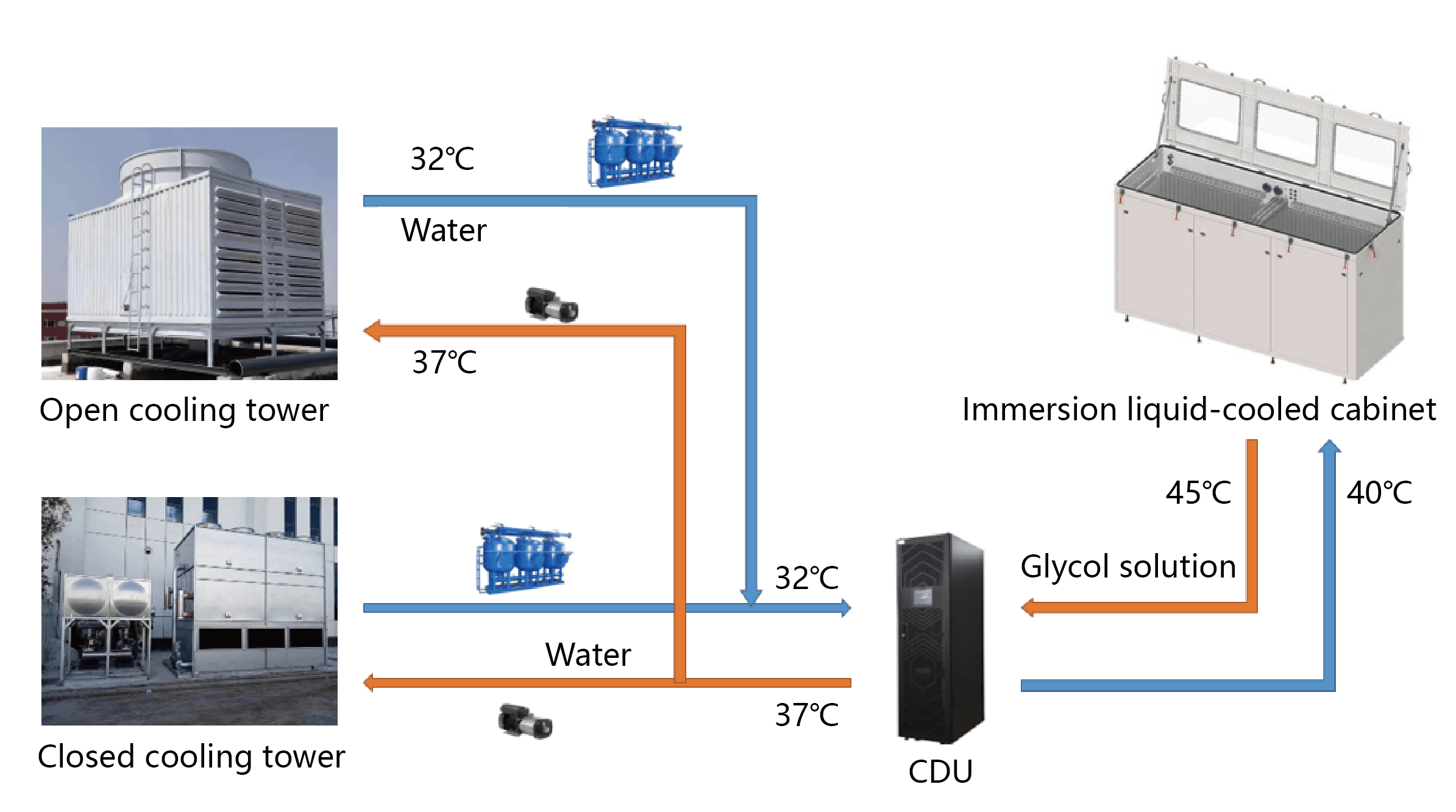

The cold plate liquid cooling system is mainly divided into two parts: the primary side (outdoor) circulation and the secondary side circulation (indoor). The heat transfer on the primary side is achieved by the increase or decrease of water temperature, while the secondary side circulation is achieved by the increase or decrease of coolant temperature.

The primary side system consists of outdoor heat dissipation equipment, circulating water pumps, constant pressure water supply devices, water treatment devices and pipelines. Its cold source adopts mechanical refrigeration system and natural cooling system to respond to different temperature requirements at the secondary side terminal.

The secondary side system consists of heat exchange cold plate, cold distribution unit, circulation pipeline, cold source and other components. The secondary side liquid loop is designed from the cold distribution unit to the rack, connected to the IT equipment through the circulation pipeline, and then returned to the cold distribution unit through the circulation pipeline.

The Coolant Distribution Unit (CDU) is a key component in the heat dissipation process. It is mainly composed of a plate heat exchanger, an electric proportional valve, a secondary circulation pump expansion tank, a safety valve, special joints for inlet and outlet water pipes, a controller and its panel, etc. It is used for heat exchange between the primary and secondary systems and controls the coolant flow and temperature.

In addition, as part of the electronic equipment, the heat exchange cold plate is integrated into the liquid cooling server, improving the integrity and stability of the liquid cooling system.

4. Advantages of cold plate liquid cooling technology

High efficiency: Coolant replaces part of the air as the heat exchange medium, and combined with air-cooled air-conditioning equipment, it significantly improves the heat dissipation efficiency;

High-density deployment: Efficient heat exchange capability continuously improves cabinet power density to adapt to high computing power scenarios;

High reliability: Leakage detection, fault warning and safety monitoring mechanisms ensure stable system operation;

Energy saving and consumption reduction: Greatly reduce the proportion of mechanical refrigeration equipment used and reduce overall energy consumption;

Support system transformation: Cold plate liquid cooling is compatible with the existing air-cooled computer room system and can be directly connected to the original system through simple system transformation.

5. Analysis of common liquid cooling transformation solutions

① Liquid cooling transformation of shared chilled water system

Renovation plan: The system consists of air cooling + liquid cooling; air cooling and liquid cooling share a set of cold sources, both provided by cooling towers and chillers, and connected to the liquid-cooled CDU from the chilled water pipeline ring network; add a liquid-cooled CDU and a liquid-cooled secondary side pipeline ring network;

Features: Utilize the existing cold source and directly connect to the primary side of the liquid cooling system through the chilled water pipeline ring network, with low transformation difficulty;

Benefits after transformation: The use of cold plate liquid cooling cabinets has improved the power density of the cabinets, increased the effective use area of the computer room, and reduced the noise in the computer room and the damage rate of the core components of IT equipment.

② Liquid cooling transformation of shared cooling water system

Renovation plan: The system adopts air cooling + liquid cooling; air cooling and liquid cooling share a set of cooling sources, and liquid cooling directly uses the cooling tower as the primary side of liquid cooling, and is connected to the liquid cooling CDU from the cooling water pipeline ring network; a new liquid cooling CDU and liquid cooling secondary side pipeline ring network are added;

Features: Only the original cooling water system is changed, most of the chillers can be shut down, significantly reducing energy consumption; at the same time, a new water filtration device is added on the primary side of the liquid cooling, which can effectively ensure the water quality entering the liquid cooling CDU;

Benefits after transformation: Reduced power consumption of equipment other than IT equipment in the computer room, lowered the PUE value of the computer room, and also increased the power density of the computer room cabinets and the effective use area of the computer room.

As chip performance continues to improve, the market demand for efficient heat dissipation technology is also growing. To meet this challenge, cold plate liquid cooling strives to achieve breakthroughs in various aspects such as the thermal conductivity of cold plate materials, intelligent control systems, and waste heat recovery. In the future, as the technology matures, standards improve, and the scale of application expands, cold plate liquid cooling will be more widely used in the data center field.