Innovative application and technological breakthrough of FerroTec semiconductor chiller in the coating and developing process

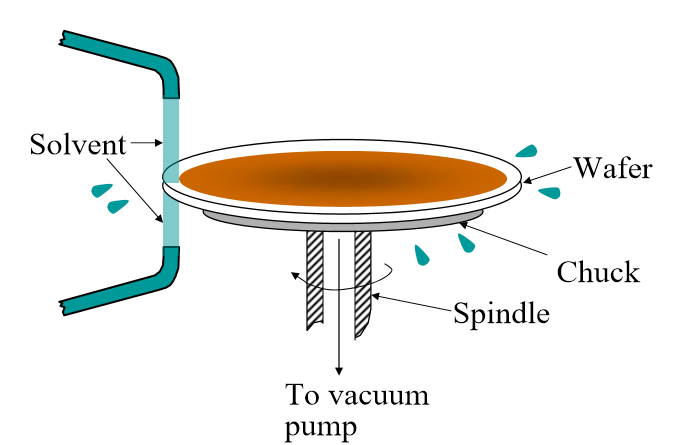

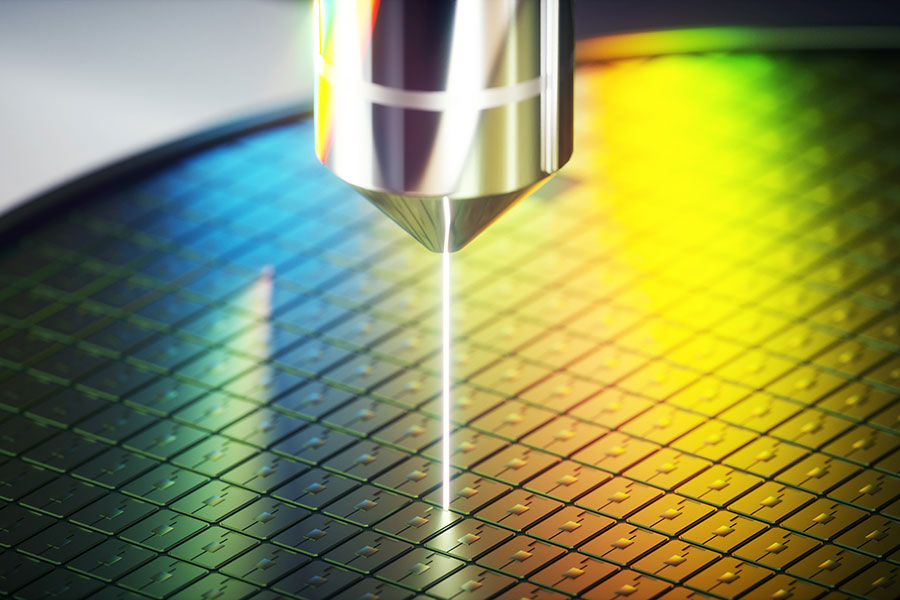

In the front-end process of semiconductor manufacturing, the temperature stability of the coating and developing equipment is directly related to the viscosity control, coating uniformity and developing reaction rate of the photoresist. In the coating process, the photoresist is dripped onto the surface of the wafer through the glue head, and the vacuum suction cup sucks the wafer and rotates at high speed to spread the glue. After the coating is completed, the film is baked and the organic solvent in the photoresist is volatilized by the heating plate to form an ultra-thin photoresist film.

During this process, the heating plate is prone to uneven heating, which prevents some organic solvents in the photoresist from being effectively volatilized, affecting the quality of the final film. Experimental data shows that when the temperature fluctuation of the developer tank exceeds ±0.5℃, the critical dimension (CD) deviation will increase by 35%, seriously affecting the yield of processes below 28nm.

1. Temperature control challenges in the coating and developing process

(I) Sensitivity of photoresist properties to temperature

● Taking ArF photoresist as an example, its viscosity temperature coefficient is -0.04 Pa·s/℃, and a temperature fluctuation of 1℃ will result in a coating thickness difference of 2.3nm

● Relationship between the reaction rate of developer (such as 2.38% TMAH) and temperature: For every 1°C increase in temperature, the development speed increases by 7-10%.

(II) The impact of temperature fluctuations on coating development

The ±0.5℃ fluctuation of traditional chillers will cause:

● Uneven edge exposure (Edge Bead Removal deviation)

● Development residual defects (Defect density increased by 20%)

● Shortened equipment life due to chemical corrosion (ordinary stainless steel pipes can only last 6-12 months)

2. Core technology breakthrough of FerroTec chiller

FerroTec TEC series chillers achieve high-precision temperature control of ±0.01℃ through PID, ensuring the surface uniformity and consistency of the glue coating and improving the wafer yield. They are becoming the preferred temperature control solution for glue coating and developing equipment in the world's leading wafer fabs.

▲High-precision PID temperature control technology

▲PID temperature control model

In order to improve the performance of the PID temperature control algorithm, FerroTec optimized and upgraded the chiller temperature control system based on this model, achieving an instantaneous control accuracy of ±0.05℃.

● Parameter setting: Adjust PID parameters through experiments or experience to obtain the best temperature control effect.

● Filtering: Filter the sensor data to reduce noise interference during system operation.

● Adaptive control: Adaptively adjust PID parameters according to the dynamic characteristics of the system.

3. Chiller application case: Gluing and developing field

▲FerroTec chiller series - suitable for coating and developing

FerroTec chillers control the photoresist viscosity fluctuation within ±0.5% through precise temperature control of ±0.01°C, thereby improving the uniformity of wafer edge exposure and helping customers improve the yield of semiconductor manufacturing processes. Currently, the above TEC series Chillers have been applied to international advanced process production lines.