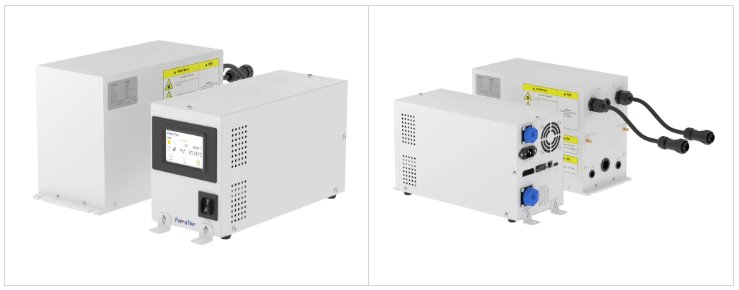

FerroTec Special Liquid Chiller: A TEC style chiller designed specifically for highly corrosive liquids!

In high-tech fields such as semiconductor manufacturing, precision electronics, and laboratory research, strong acid and alkali solutions such as hydrofluoric acid, sulfuric acid, and nitric acid are often needed to achieve ideal process effects. At this time, a professional temperature control device is needed to maintain the temperature of these special liquids in the optimal range. For this reason, FerroTec has launched a series of special liquid chillers: This series of equipment is specially designed for liquid temperature control scenarios with high corrosion and high purity requirements, and can achieve stable operation and high-precision temperature control in highly corrosive environments.

1. ±0.01℃ high precision temperature control

2.1000W cooling capacity and 2200W heating capacity

3. Circulating fluid temperature range 10℃~60℃

4. Compatible with various types of corrosive circulating fluids

5. Multiple models available/support product customization

1. Wide circulating fluid temperature range

This series of temperature control equipment has a wide temperature range adjustment capability of 10℃~60℃, which can be flexibly adapted to various high-precision temperature control processes, providing stable temperature control guarantee for diversified industrial applications;

2. High cooling/heating capacity

This series of temperature control equipment can meet the cooling demand of 0~1000W and the heating demand of 0~2200W . Its cooling and heating capacity change with the change of circulating fluid temperature, which can meet the diverse temperature control needs of customers. The following figure takes FCTC10201-2101 as an example (the cooling capacity of this equipment is 1000W) to specifically show the changing trend of cooling/heating capacity with temperature;

▲FCTC10201-2101 cooling/heating capacity curve

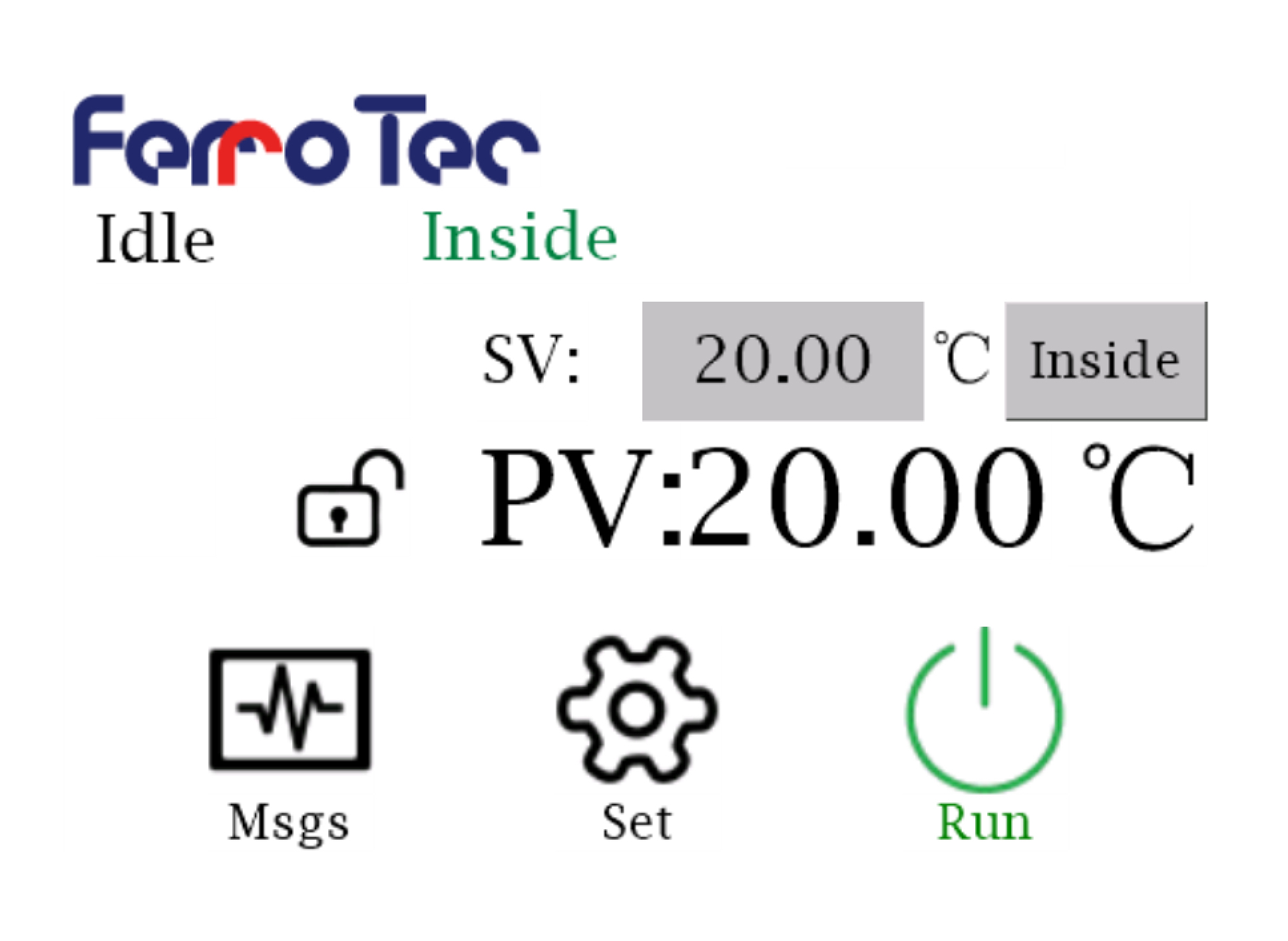

3. High-precision temperature control

This series of temperature control equipment has a temperature control accuracy of up to ±0.01℃ , and has a built-in 4-wire PT100 temperature detector that can monitor the circulating fluid temperature at the inlet and outlet in real time. At the same time, the machine is equipped with a temperature compensation function to ensure the stability and consistency of temperature control during long-distance transportation;

▲Temperature control interface

4. Clear internal structure

This series of temperature control equipment adopts modular design, with independent layout of the electronic control unit and the refrigeration unit, clear structure and reasonable space planning, which is convenient for daily operation and later maintenance;

5. Multiple types of circulating fluids are available

This series of temperature control equipment can be adapted to a variety of highly corrosive liquids , providing reliable temperature control support for special process scenarios;

▲ Available circulating fluid name

6. Multiple security protections

To ensure the safety of equipment operation and the reliability of user operation, the chiller system is equipped with multiple safety protection mechanisms:

• Over temperature protection

• Leak detection

• Sensor abnormality alarm

• Refrigeration system overload protection

These safety mechanisms effectively prevent abnormal situations from affecting the equipment and ensure the stability of the equipment's temperature control.

Equipment parameters: