How to cope with high computing power demand? Liquid cooling technology helps data center upgrade (next issue)

Hello everyone! In the last issue, we introduced the cold plate liquid cooling in detail . In this issue, we will continue to have a deeper understanding of the working principle and technical advantages of another mainstream liquid cooling form - immersion liquid cooling. To help you better understand, let's quickly review the main categories of liquid cooling technology:

① Direct contact liquid cooling: The coolant is in direct contact with the chip, including single-phase immersion liquid cooling, phase change immersion liquid cooling (two-phase immersion liquid cooling) and spray liquid cooling.

② Indirect contact liquid cooling: The coolant takes away the heat indirectly through the cold plate and does not directly contact the chip. It mainly includes single-phase cold plate liquid cooling and phase change cold plate liquid cooling.

1. What is immersion liquid cooling?

Immersion liquid cooling is a technology that directly immerses heat-generating electronic components in a coolant for heat exchange. Depending on whether the coolant undergoes phase change, it can be divided into two categories: single-phase immersion liquid cooling and phase change immersion liquid cooling (two-phase immersion liquid cooling).

2. Working principle of immersion liquid cooling

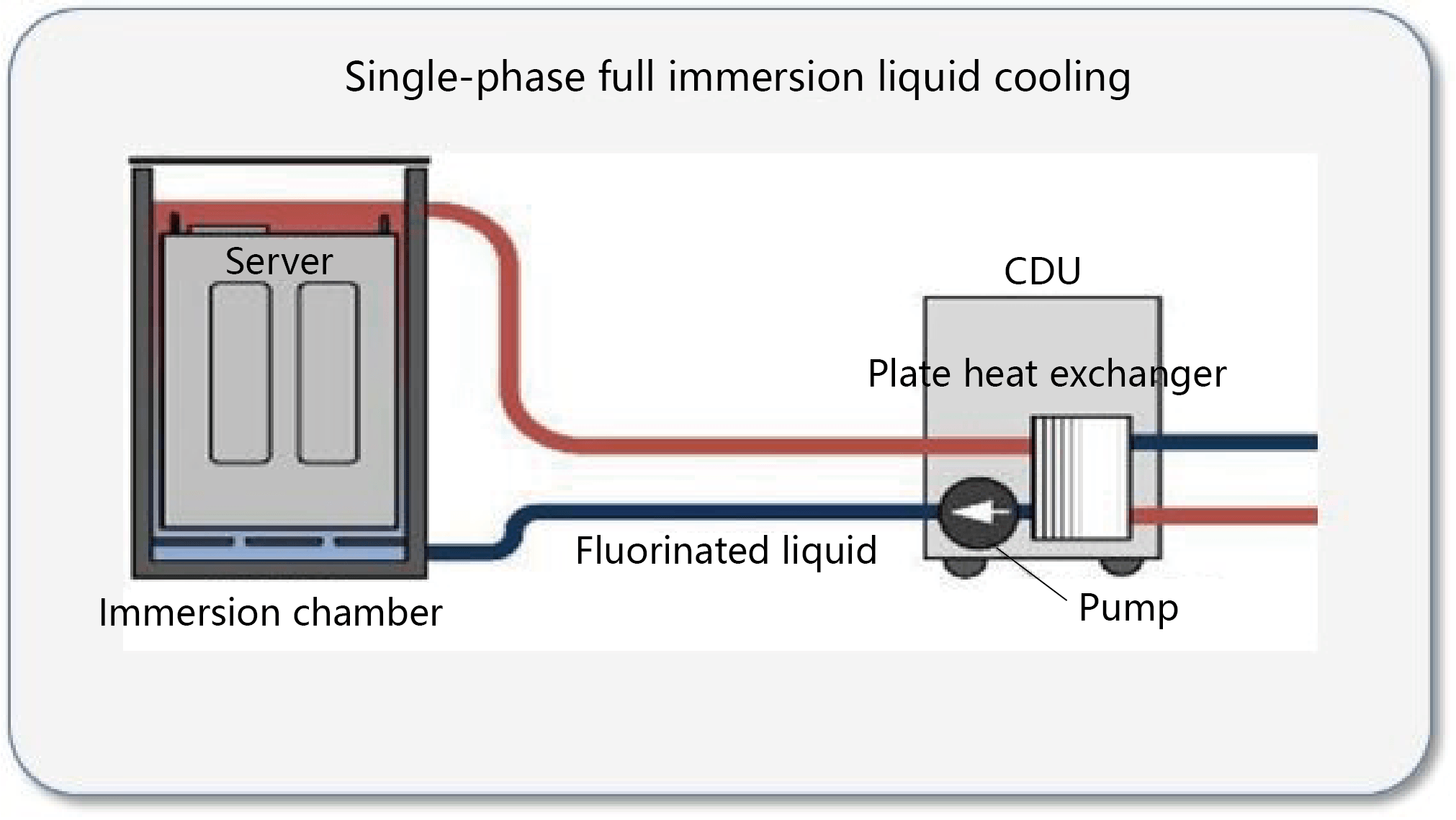

① Single-phase immersion liquid cooling: Single-phase immersion liquid cooling usually uses high-boiling point coolants, such as hydrocarbons (mineral oil, vegetable oil, etc.) or silicone-based oils. This type of coolant always remains in liquid form during the circulation process and does not undergo phase change, so it is called "single-phase" liquid cooling.

The core of the system is the Coolant Distribution Unit (CDU), which consists of a liquid pump, plate heat exchanger, filter, solenoid valve, flow meter, temperature and pressure sensors, and pipelines.The liquid pump provides circulation power for the system, driving the coolant to flow in the closed tank cavity to absorb the heat generated by electronic components. The coolant carrying heat then enters the CDU, exchanges heat with the low-temperature liquid from the outdoor primary cooling system, and returns to the tank cavity after heat dissipation, achieving a continuous and efficient circulation cooling process.

▲Single-phase immersion liquid cooling

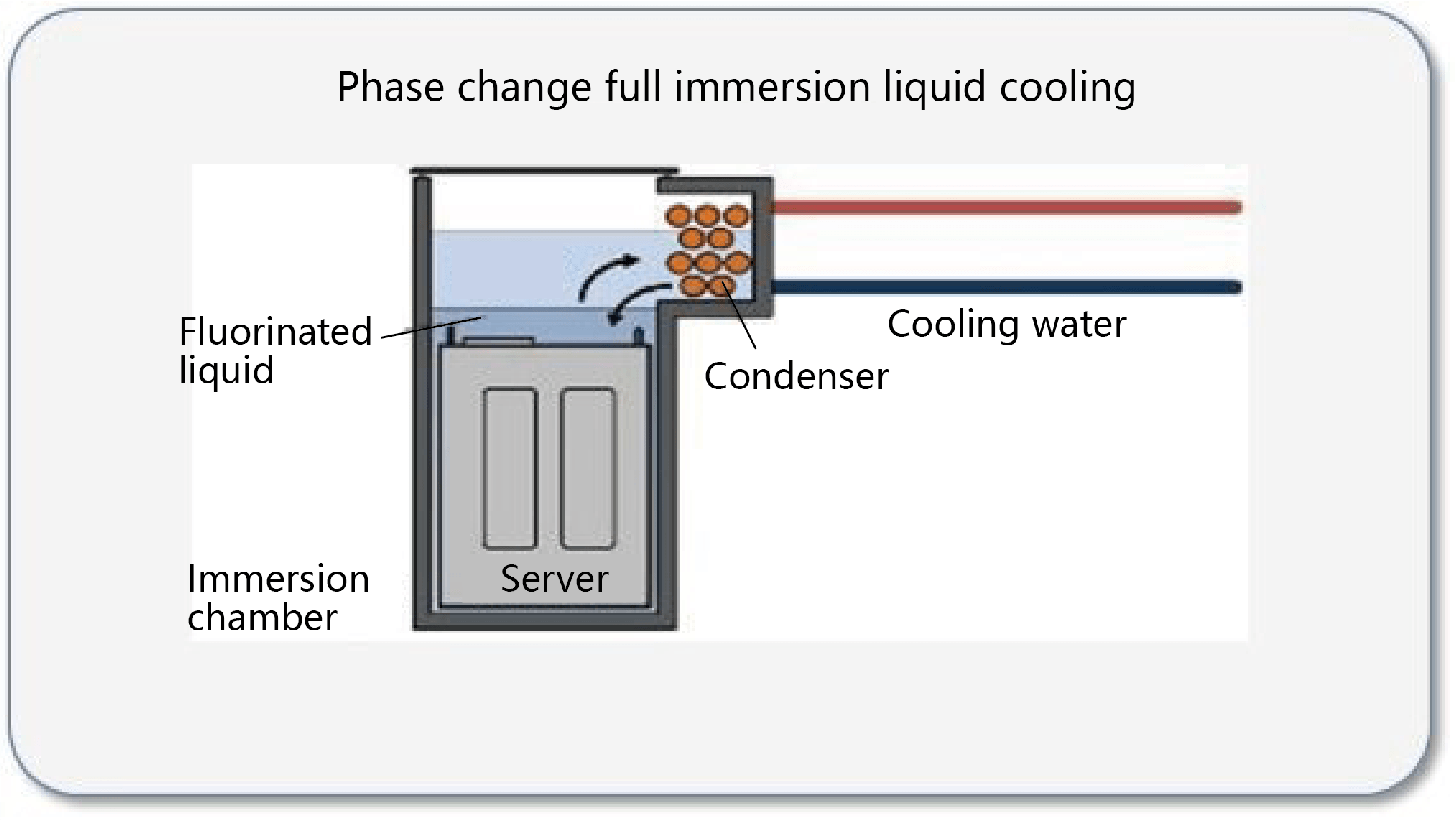

② Phase change immersion liquid cooling: Phase change immersion liquid cooling usually uses low boiling point coolant (fluorinated liquid, etc.). During the cycle heat dissipation process, the coolant will undergo a phase change process from liquid to gas and then condense from gas to liquid, thereby achieving efficient heat exchange.

The coolant is sealed in the immersion chamber. After absorbing the heat generated by the IT equipment, the temperature rises and it starts to boil after reaching the boiling point, transforming from liquid to gas, forming a large amount of steam. The steam rises above the liquid surface and forms a gas phase in the chamber.The coolant vapor in the gas phase releases heat after contacting the water-cooled condenser, condenses into liquid, and falls back into the cavity in the form of droplets to continue circulating. The heated cooling water in the condenser discharges heat through the primary side circulation system.

▲Phase change immersion liquid cooling

3. Technical advantages of immersion liquid cooling

High efficiency: The thermal conductivity of cooling liquid is much better than that of air, which can significantly reduce the PUE value of data centers. According to official data, the average PUE value of large data centers around the world is 1.57, while the PUE value of immersion liquid cooling is generally lower than 1.1;

High-density deployment: Immersion liquid cooling can support a single rack power of 100kW or even more than 200kW, which is much higher than the 10-15kW supported by traditional air cooling systems, fully meeting the needs of high-performance computing scenarios.

High reliability: IT equipment is completely immersed in coolant, which can effectively isolate external interference such as dust, moisture and vibration. It can run stably while reducing equipment noise and failure rate.

Water and energy saving: The coolant can operate stably in high temperature environments (up to 45°C), making full use of natural cooling resources, reducing water consumption and carbon emissions, and promoting the development of data centers in a green and sustainable direction.

*PUE (Power Usage Effectiveness) is a key indicator for measuring the energy efficiency of a data center. The closer the PUE value is to 1.0, the higher the energy utilization efficiency of the data center and the less energy is wasted.

With the rapid growth of computing power demand, data centers have an increasing demand for efficient cooling solutions. Immersion liquid cooling is gradually becoming an important technical direction for the construction of new data centers with its advantages of high efficiency, high reliability, water saving and energy saving, providing strong support for building a green and intelligent data center ecosystem.