Chiller Science Class| How to Choose a Compressor-Type Air-Cooled/Water-Cooled Chiller

Welcome to Chiller's Science Corner! In practice, customers often ask, "When controlling the temperature of equipment, should I choose an air-cooled or water-cooled chiller?" The answer depends on the specific application conditions. In this episode, we'll explain in detail the working principles, advantages, and typical application scenarios of air-cooled and water-cooled compressor chillers. If you have any questions about the article or want to learn more about chillers, feel free to leave a comment below!

I. Working Principle of Air-Cooled/Water-Cooled Compressor Chillers

First, regardless of whether it's air-cooled or water-cooled, the core principle of a compressor-type chiller is the same: through refrigerant circulation, the heat generated by the equipment is carried away from the cooling liquid (usually water or ethylene glycol solution) and finally discharged to the external environment. The main difference between air-cooled and water-cooled temperature control lies in the form of heat dissipation.

Air-cooled: A fan forces air to flow over the condenser, directly dissipating heat into the surrounding air. The entire unit is a standalone unit, requiring no external water supply; it can be used simply by plugging it in.

Water-cooled type: It relies on cooling water flowing through the condenser to remove heat, and then the hot water is cooled down by an external system and circulated for reuse. The system needs to be equipped with water pumps, pipelines, or cooling towers, etc.

II. Advantages of Air-Cooled/Water-Cooled Compressor Chillers

☑️Air -cooled: Convenient to use, but limited by the environment

Air-cooled compressor chillers are easy to install, requiring no external water source or piping; they are also relatively simple to maintain, making them suitable for temporary deployment or mobile use.

However, its drawbacks are as follows: First, its heat dissipation efficiency is greatly affected by ambient temperature. For example, when the workshop temperature exceeds 35℃, the chiller's cooling capacity will decrease by 15% to 30%. Second, it is quite noisy during operation, typically between 65 and 80 decibels, approaching the operating noise of a small air conditioner outdoor unit. Finally, sufficient ventilation space needs to be provided for the chiller during installation; otherwise, poor heat dissipation may trigger high-pressure protection shutdown, affecting production progress.☑️Water-cooled: Stable and efficient, but requires high initial investment.

Water-cooled compressor chillers offer stable heat dissipation, virtually unaffected by ambient temperature. Compared to air-cooled compressor chillers, they have a higher energy efficiency ratio and are more energy-efficient in long-term operation. Furthermore, they operate with lower noise levels, making them suitable for use in noise-sensitive environments such as laboratories and hospitals.

However, its drawbacks are as follows: First, its internal system is complex, requiring a supporting cooling water system, including water pumps, pipes, water supply devices, and rooftop cooling towers. Second, long-term use of hard water easily leads to scale buildup, which affects heat exchange efficiency and can even clog pipes. To prevent scale buildup, softened water needs to be used, or scale inhibitors need to be added regularly, which increases its initial investment cost.Assuming the equipment operates for more than 8 hours a day, the initial investment difference can typically be recovered in 2-3 years through energy savings.

III. Application Scenarios of Air-Cooled/Water-Cooled Compressor Chillers

Application scenarios of air-cooled compressor chillers:

☑️Low -power equipment : 1~3kW laser marking machines, small CO₂ engraving machines, desktop 3D printers, etc.;

☑️Locations where access to a water source is inconvenient: rented factory buildings, temporary workshops, outdoor exhibitions, etc.;

☑️Low usage frequency: It only runs for a few hours a day and is not a continuous operation;

☑️For those with limited budgets or who need to start production quickly: air-cooled chillers are ready to use immediately upon purchase, requiring no civil engineering or piping construction.

Application scenarios of water-cooled compressor chillers:

☑️High -power equipment: Fiber laser cutting machines of 5kW and above, semiconductor cleaning equipment, MRI medical imaging systems, etc.;

☑️High -precision temperature control requirements: Scenarios requiring ±0.1℃ and higher temperature control accuracy, such as precision optics and wafer fabrication processes;

☑️High -temperature environment: If the workshop temperature exceeds 35℃ in summer, the efficiency of air cooling will drop sharply, while water cooling is more reliable.

☑️Supply with cooling infrastructure: The factory itself already has cooling towers or a central water system, resulting in low connection costs;

☑️Low noise requirement : Quiet places such as hospital dental clinics and research laboratories.

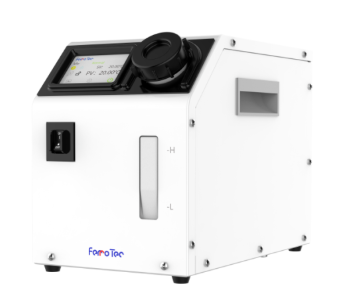

FerroTec Group (China) Co., Ltd. was established in 1992 and is headquartered in Hangzhou, Zhejiang Province. With a production base of nearly 50,000 square meters in China, we have focused on thermoelectric refrigeration and precision temperature control technology for over 30 years. R&D investment accounts for nearly 8% of our revenue, and we have obtained over 200 invention patents related to refrigeration. We offer a wide range of chillers and customized services to meet the precision temperature control needs of various industries, including semiconductor manufacturing, laser industry, CNC machine tools, and medical devices. We can provide customized temperature management solutions. Contact us at 0571-87977390.