Chiller Science class:Choosing the wrong throttling device will significantly reduce the efficiency of your chiller!

In a vapor compression refrigeration cycle, the compressor, condenser, throttling device, and evaporator are four indispensable components, together forming a closed-loop system. Among them, the throttling device, although simple in structure, plays a crucial role in establishing high and low pressure differences and precisely controlling refrigerant flow. This article will provide a detailed introduction to the main types of throttling devices, their core functions, and their respective technical characteristics.

I. Main functions of throttling devices

In a vapor compression refrigeration cycle, the refrigerant flowing from the condenser is a medium-temperature, high-pressure saturated liquid. For it to effectively absorb heat in the evaporator, its pressure and temperature must first be reduced to meet the requirements of the current operating conditions. The throttling device is the key component for accomplishing this "pressure and temperature reduction" task. It creates local resistance through small orifices, narrow channels, or adjustable valves, causing the high-pressure liquid refrigerant to expand rapidly. During this process, some of the liquid vaporizes instantaneously, forming a low-temperature, low-pressure gas-liquid two-phase mixture, which then enters the evaporator to absorb heat. Furthermore, the throttling device also plays a crucial role in precisely regulating the refrigerant flow rate.

☑️Prevent excessive liquid refrigerant from entering the evaporator to avoid "liquid slugging" in the compressor due to liquid intake;

☑️Prevent insufficient liquid supply, ensure sufficient heat exchange in the evaporator, and maintain the system's cooling capacity.

Therefore, the throttling device is not only a "converter" that realizes pressure drop and phase change, but also a core component to ensure the system's energy efficiency, stability and safe operation.

II. Different Classifications of Throttling Devices

Throttling devices in refrigeration systems are mainly divided into two categories: fixed orifice type and variable orifice type. As the name suggests, the flow cross-sectional area of the fixed orifice type remains constant; while the variable orifice type can dynamically adjust the flow area according to the system operating status (such as load, pressure difference, etc.) to achieve more precise flow control.

1. Fixed Orifice Throttling Device:

☑️Capillary Tube: The capillary tube is the simplest fixed-orifice throttling device. It consists of a slender copper tube with an inner diameter of 0.5~2.5 mm and a length of 1~6 m. It has no moving parts, making it low-cost and highly reliable. The flow rate of a capillary tube depends entirely on the pressure difference between the high-pressure and low-pressure sides of the system. Therefore, it is only suitable for small, fixed-frequency equipment with stable loads and minimal changes in operating conditions, such as household refrigerators and window air conditioners.

2. Variable Orifice Throttling Device:

☑️Automatic Expansion Valve (AEV): An automatic expansion valve maintains a relatively constant pressure by detecting the pressure at the evaporator outlet, thereby indirectly controlling the refrigerant flow. However, relying solely on the pressure signal is insufficient to determine whether the refrigerant has completely evaporated. Therefore, when operating conditions change, problems such as excessive refrigerant supply (potentially causing liquid slugging) or insufficient refrigerant supply (deteriorating cooling performance) can easily occur. Furthermore, due to its limited temperature control accuracy, automatic expansion valves have now been largely replaced by more advanced expansion valves.

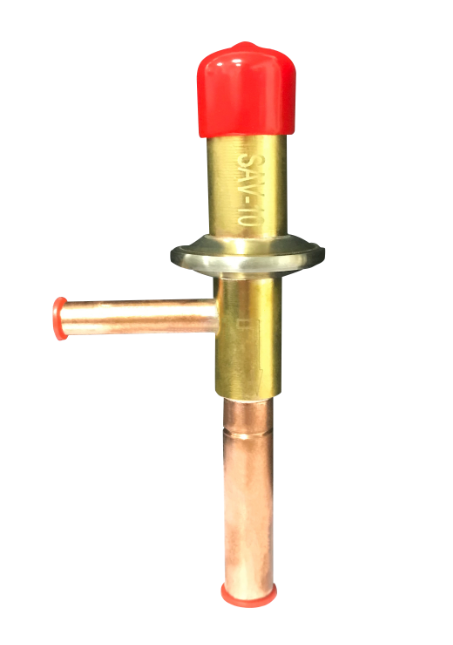

☑️Thermostatic Expansion Valve (TXV): The thermostatic expansion valve senses the temperature through a sensor installed at the evaporator outlet and, combined with the upstream pressure, automatically adjusts the valve opening to ensure complete refrigerant vaporization within the evaporator and maintain a stable superheat (preventing liquid refrigerant from flowing back to the compressor). As a purely mechanical device, it requires no external power supply and operates stably and reliably. Based on the internal pressure drop of the evaporator, it is divided into two types: internally balanced and externally balanced. When the evaporator resistance is high and the pressure drop is significant, the externally balanced type is recommended. Thermostatic expansion valves are currently widely used in commercial freezers, central air conditioning systems, and industrial refrigeration equipment, and are the most mainstream variable throttling solution.

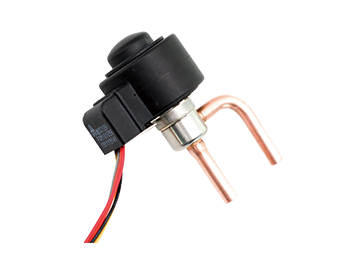

☑️Electronic Expansion Valve (EEV): The electronic expansion valve is driven by a stepper motor. The system monitors the temperature and pressure at the evaporator outlet in real time through sensors. The controller then uses intelligent algorithms (such as PID control) based on this data to quickly calculate the most suitable valve opening and adjust it in real time.

Compared to mechanical valves, electronic expansion valves offer advantages such as fast response time (milliseconds), high control precision, compatibility with variable frequency compressors for optimized operation, and support for remote monitoring and intelligent diagnostics. They are suitable for applications with extremely high energy efficiency and stability requirements, such as high-end heat pumps, thermal management in new energy vehicles, and data center cooling. Currently, most FerroTec chillers utilize electronic expansion valves to achieve precise control of refrigerant flow, thereby improving the overall performance and energy efficiency of the chiller system.

III. The Development History of Throttling Technology

From capillary tubes to electronic expansion valves, the evolution of throttling devices reflects the continuous improvement of refrigeration systems in energy efficiency, adaptability to operating conditions, and control precision.

☑️Early models, represented by capillary tubes, focused on simple structure and reliable operation to meet basic refrigeration needs;

☑️Mechanical feedback devices such as the thermal expansion valve (TXV) were introduced in the mid-term to achieve adaptive regulation based on superheat;

☑️ Nowadays, relying on electronic control and sensing technologies, millisecond-level response, high-precision regulation and intelligent management can be achieved through electronic expansion valves (EEV).

This technological upgrade ensures the high efficiency, safety, and stability of the refrigeration system in real-world operating environments with wide temperature ranges and varying loads.

In chiller systems, the throttling device, though compact in structure, is a crucial link in the refrigeration cycle. It not only reduces refrigerant pressure and performs phase change, but also directly affects the system's energy efficiency, stability, and temperature control accuracy. A thorough understanding of the working principle and applicable scenarios of throttling devices helps us to more rationally select, design, and maintain chillers in practical applications.