Chiller Science Class | How to maintain a compressor chiller? These details must be paid attention to!

Usage environment: affecting heat dissipation and operating stability

The heat dissipation performance of a chiller is closely related to the operating environment. Air-cooled and water-cooled chillers have different requirements for their operating environments due to their different cooling methods.

Compressor air-cooled models :

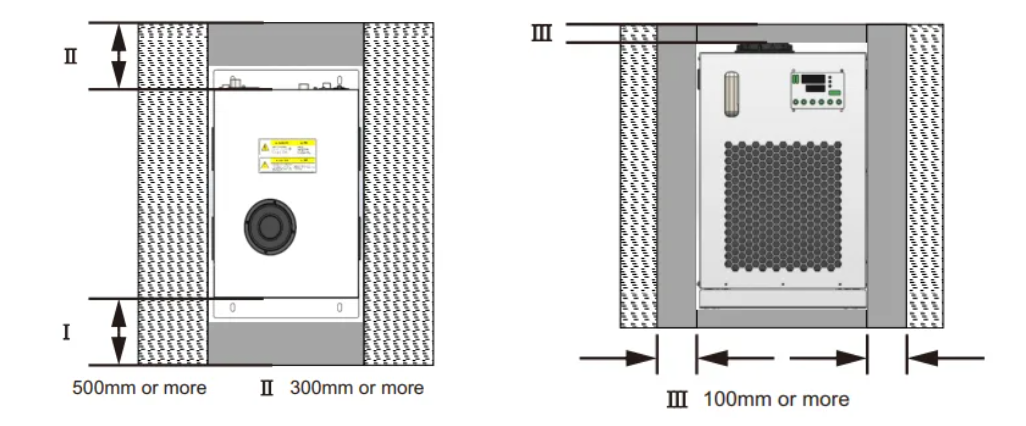

1. Ensure ventilation space: Sufficient space should be reserved around the equipment to ensure smooth air inlet and outlet to avoid poor heat dissipation caused by hot air backflow.

2. Control ambient temperature: Excessively high ambient temperature will cause the condensing pressure to rise, reducing cooling efficiency. In severe cases, it may trigger overheating protection and cause equipment shutdown. It is recommended to install the chiller in an environment where the temperature does not exceed 35°C, and the maximum temperature should not exceed 40°C.

3. Clean the filter regularly: The filter at the air inlet of the equipment is prone to dust accumulation, which affects the air volume, increases energy consumption, and even accelerates the aging of components. It is recommended to check and clean it at least once a month.

Compressor water-cooled models :

1. Ensure the cooling water circulation: Before use, check whether the inlet/outlet valves are open and whether the pipes are bent or blocked to prevent high pressure alarm or shutdown due to poor water flow.

2. Monitor cooling water quality: Poor water quality can easily lead to scaling or corrosion in the condenser, affecting cooling efficiency and equipment life. It is recommended to use softened or purified water and replace it regularly to prevent algae and impurities from entering the system.

Circulating water system: closely related to equipment performance

The circulating water of the chiller is connected to the client's core heat-generating equipment (such as lasers, power modules, etc.). Once the circulation is interrupted or the temperature is out of control, it may cause the equipment to overheat, resulting in performance degradation or even damage. Therefore, we must pay close attention to the following points:

1. Select the appropriate circulating fluid: Generally, deionized water or pure water is sufficient. When the ambient temperature is below 5°C, it is recommended to add ethylene glycol antifreeze (adjust the proportion according to low-temperature requirements) to prevent the pipes from freezing. Note: Using the wrong fluid may cause system corrosion, seal aging, or cracking.

2. Keep the circulating fluid clean: Long-term operation can lead to ion accumulation and microbial growth in the water, affecting heat dissipation performance. It is recommended to replace the circulating fluid every 3–6 months or install a conductivity sensor and filter to monitor and purify the water quality and improve system stability.

3. Prevent leaks and blockages: Loose pipe joints can cause leaks, while accumulated impurities can easily cause blockages, both of which can affect circulation flow and, in severe cases, lead to cooling failure. The equipment is equipped with a liquid level switch and pressure sensor that can provide timely alarms in the event of an anomaly, helping users quickly identify and troubleshoot problems.

Overall, maintaining a high-precision chiller isn't complicated, but it does require consistent practice: regularly checking ventilation, cleaning filters, and monitoring water quality and circulation. Maintaining these key areas not only extends the life of the equipment but also ensures consistent cooling performance, making it easy to handle a variety of complex scenarios.