Chiller Science Class | An article to help you understand compressor chillers: core components + full analysis of working principles

Welcome to Chiller Science Class! According to the refrigeration principle, chillers are usually divided into compressor chillers, direct heat exchange chillers, TEC chillers and other types. This issue will focus on the core components of compressor chillers and their working principles.

1. Working principle of compressor refrigeration system

The working principle of a compressor chiller is very interesting. In simple terms, it is a process in which a refrigerant completes heat transfer and dissipation by constantly changing its state (conversion between gas and liquid), which is divided into four stages: compression, condensation, throttling and evaporation.

①The first is the compression stage : The compressor is the heart of the entire system. It sucks in low-temperature and low-pressure gaseous refrigerant and compresses it into high-temperature and high-pressure gaseous refrigerant through mechanical action.

②The second is the condensation stage : After the high-temperature and high-pressure gaseous refrigerant enters the condenser, it releases the heat in the body through heat exchange with the external environment (air or water). In this process, the gaseous refrigerant begins to cool and eventually turns into high-pressure liquid refrigerant.

③ Arriving at the throttling stage: the liquid refrigerant is depressurized through throttling elements such as expansion valves or capillaries, and converted into low-temperature and low-pressure liquid refrigerant.

④Finally , it enters the evaporation stage: the liquid refrigerant enters the evaporator, absorbs heat from the surrounding medium, and turns back into gas. During this process, the surface temperature of the evaporator will decrease, and the heat will be taken away from the object or space to be cooled, thereby achieving the cooling effect. Subsequently, the gaseous refrigerant returns to the compressor and starts a new round of circulation.

The above four stages are independent of each other, but also interdependent, forming a complete refrigeration closed loop. So what are the core components that play a role in the whole process, and what different roles do they play in the refrigeration system?

2. Core components of compressor refrigeration system

In fact, the realization of the compressor refrigeration principle is based on the following four core components: compressor, condenser, throttling element and evaporator. These four core components work together to promote the compressor refrigeration system to achieve a complete heat exchange process and ensure efficient and stable operation of the equipment.

01Compressor : Power Source

The compressor is the power source of the entire chiller refrigeration system, providing sufficient power for the operation of the system. According to the working principle, compressors can be divided into two categories: reciprocating (piston type, membrane type) and rotary (vane type, screw type, rotor type). Small chillers usually use rotary compressors, which have the advantages of high stability, low noise, small size, and high efficiency (higher COP value than rotary type).

▲ Compressor

02Condenser : Heat Discharge Station

The condenser is the heat discharge station in the chiller refrigeration system, which is responsible for discharging the heat in the refrigerant to the surrounding environment. According to the cooling method, the condenser can be divided into four categories: air-cooled condensers, water-cooled condensers (such as shell and tube condensers, sleeve condensers, shell-coil condensers, spiral plate condensers, immersed condensers, etc.), evaporative and spray condensers. Small chiller equipment usually uses air-cooled condensers and water-cooled condensers. Air-cooled condensers are easy to install and do not require external equipment assistance, but they are noisy, and the heat dissipation effect will be affected by the ambient temperature. In contrast, water-cooled condensers have better heat dissipation and less noise, but they require external cooling water circuits and are more complicated to install.

▲ Working principle of condenser

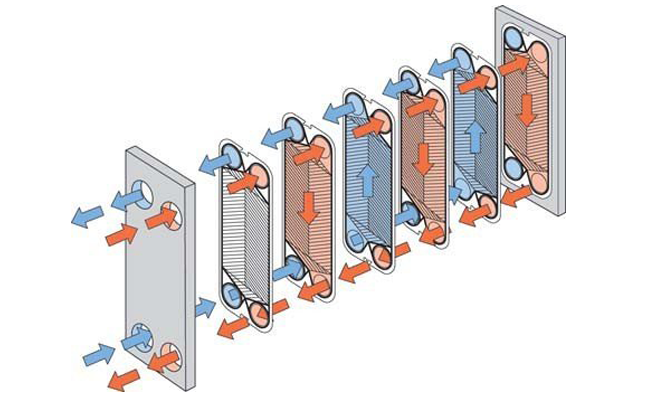

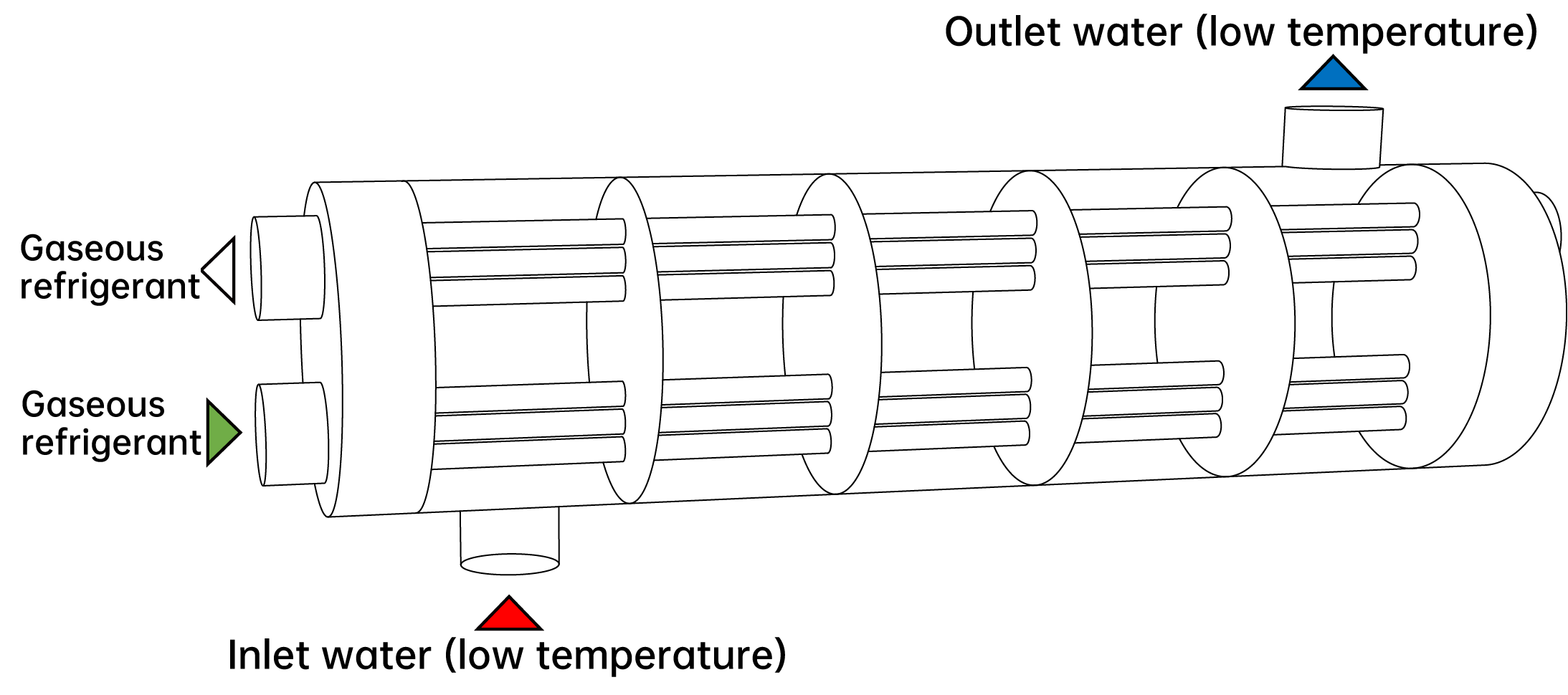

03Evaporator : Heat Absorption Master

The evaporator is a heat absorber in the chiller refrigeration system. Its function is to absorb the heat from the surrounding air and allow the refrigerant to complete the transformation from liquid to gas. Common evaporators are plate, tube and fin types, each with its own advantages and limitations. The plate evaporator has high heat transfer efficiency and small size, but the pressure and temperature adaptability range is small; the tube evaporator has high heat exchange efficiency, good sealing, and a wide range of applications, but the structure is complex and difficult to clean; the fin evaporator has good heat dissipation effect, small size, and light weight, but poor corrosion resistance, easy to clog, and easily affected by ambient temperature. The above three evaporators are very commonly used in small chillers.

▲ Working principle of evaporator

04Throttling element: controlling flow

The throttling element is a very important component in the chiller refrigeration system. It has two main functions: one is to reduce the pressure of the high-pressure refrigerant, and the other is to adjust the refrigerant flow according to the load change. Common throttling elements include thermal expansion valves, electronic expansion valves, capillaries, throttling short tubes, float valves, etc. In practical applications, many small chillers prefer to use capillaries. Because compared with other chillers, it has the advantages of low price, simple structure, and not easy to damage.

▲ Working principle of throttling element

Through today's popular science introduction, I believe everyone has a clear understanding of the core components and working principles of compressor chillers. In the next issue, Xiaocool will focus on introducing other components of compressor chillers (fans, high and low pressure switches, dry filters, etc.) in addition to the core components. Stay tuned!