New product launch: Compressor type low temperature chiller FCCWS051

The FCCWS051-7402 series chiller is a compressor-type low-temperature chiller independently developed by FerroTec Thermoelectric Division . This product can meet the application needs of laboratory research, medical industry, industrial applications, electronic components, automobiles, optical communications, aerospace, semiconductor industry etching equipment, CMP, mold temperature control and other fields; it provides stable and precise temperature control for different process steps, thereby ensuring the quality and performance of semiconductor devices.

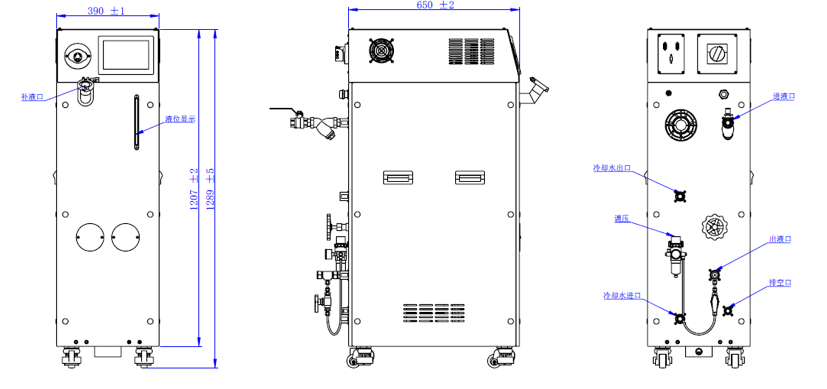

Product details

Product Features

01 Temperature range

It can provide circulating fluid temperature from -20℃ to 80℃ according to the customer's specific application scenarios , covering a wide range of industrial application needs.

02 High-precision temperature control

The built-in thermistor (RTD, resistance temperature detector) monitors the circulating fluid temperature at the inlet and outlet in real time to ensure an accuracy of up to ±0.1°C within the operating temperature range . In addition, the machine is equipped with a temperature compensation function to ensure the temperature accuracy of the circulating fluid in long-distance transportation and provide stable and reliable temperature control.

03 Precise control system performance

Built-in flow meter and pressure sensor (from Tokyo Keiso) to accurately adjust the circulating fluid flow and pressure through the bypass valve. All real-time data can be displayed on the machine screen for easy monitoring and adjustment by the user.

04 Efficient Cooling

Laboratory tests show that the equipment can achieve a maximum cooling capacity of 4kW when outputting -20℃ circulating liquid, and the circulating liquid flow rate can be maintained at 25L/min , ensuring efficient and stable cooling effect.

05 Intelligent control program

The equipment can realize PID automatic adjustment function, and each temperature stage can quickly reach a stable temperature state.

06 Remote control

Supports remote/local mode switching, customers can directly perform remote control and monitoring by controlling the computer, improving management convenience.

07 Adapt to complex application scenarios

The optimized internal circulating liquid pipeline design enables long-distance piping and high-low drop applications. With a 40-meter piping and high drop, it only takes about 1 minute to complete liquid replenishment and air exhaust. At the same time, the length of the internal pipeline is shortened, which improves energy efficiency while ensuring the beauty of the machine.

08 Energy saving and emission reduction

The compressor and water pump of the thermostat are both variable frequency designs, which can dynamically adjust the power according to the actual usage scenario to achieve energy saving and consumption reduction. The refrigerant used in the refrigeration cycle system is R410A, and the ozone depletion coefficient is 0.

09 High cleanliness

The machine has been carefully cleaned several times before leaving the factory to ensure that the pipeline is clean and pollution-free, and customers can put it into use directly. The machine has its own filter to effectively prevent pollutants from entering the client during subsequent use, ensuring the long-term stable operation of the system.

10 Equipped with filter pressure reducing valve

The equipment is equipped with SMC's filter pressure reducing valve to ensure that the circulating fluid in the circuit can be quickly and completely drained after use, simplifying the maintenance process.

11 Obtained SEMI certification

The equipment has passed SEMI certification and meets the high standards of the semiconductor industry for cooling equipment. It has excellent performance in stability, precise control, cleanliness, reliability and environmental adaptability, and is particularly suitable for high-end application fields such as semiconductor manufacturing, laser equipment, and precision instruments.

12 safety features

The equipment has a complete safety protection structure and functions, including over-temperature protection, liquid-free protection, low liquid level protection, pump overload protection, low flow protection, leakage protection, sensor abnormality protection, refrigeration system overload protection and emergency shutdown protection, etc., to ensure the safety and reliability of user operation.

13 Support product customization

The internal design of the equipment supports customization, which is convenient for realizing the actual needs of customers and meeting different application scenarios.