From "bringing in" to "going out": FerroTec's path to localization of semiconductor temperature control equipment

With the rapid development of artificial intelligence (AI) technology, the global semiconductor industry is welcoming new growth opportunities. According to data from the Semiconductor Industry Association of the United States, global semiconductor sales are on an upward trend from 2016 to 2024, with a compound growth rate of 5.64%, and the industry has significant growth potential. According to SEMI, for five consecutive years, the global share of semiconductor sales in mainland China has remained at around 30%.

"Made in China 2025" puts forward clear requirements for the localization of semiconductor equipment:

As of 2020

Achieve a 50% localization rate for 90-32 nanometer process equipment, a 50% localization rate for key packaging and testing equipment, and a 90 nanometer lithography machine

By 2025

Achieve 30% localization rate of 20-14 nanometer process equipment and localization of immersion lithography equipment

By 2030

Realize the localization of 18-inch process equipment, EUV lithography equipment, and packaging and testing equipment

This year, China's semiconductor equipment localization substitution has entered a critical period, and the localization rate is expected to exceed 35%-50%. Against this background, FerroTec (China) Chiller closely follows national policies and actively promotes the localization transformation of the semiconductor industry.

FerroTec localization layout

1. FerroTec’s domestic semiconductor industry layout

As a leading company in the domestic semiconductor industry, FerroTec (China) has invested in more than 40 companies in China, including Hangzhou Dahe Thermo-Magnetic Electronics, Ningxia Yinhe Semiconductor, Shanghai Shenhe Thermo-Magnetic Electronics, Fulede Technology, Fulehua and Zhongxin Wafer, etc. FerroTec's main business is concentrated in the fields of semiconductor materials, precision equipment and related industrial chains, covering key links such as semiconductor silicon wafers, quartz products, ceramic materials, precision equipment and cleaning services.

(II) Domestic transformation of semiconductor temperature control business

FerroTec semiconductor temperature control business is the core industry of the group. Since its establishment, the team has continued to grow and develop. It currently has two major manufacturing bases and R&D centers in Hangzhou and Changshan, and has set up Chiller overseas offices in the United States, Europe, Japan, South Korea, Singapore, etc. FerroTec can achieve high-precision temperature control of up to ±0.01℃ through its independently developed TEC temperature control technology, reducing dependence on overseas suppliers and filling the gap in the field of high-end semiconductor temperature control technology in China.

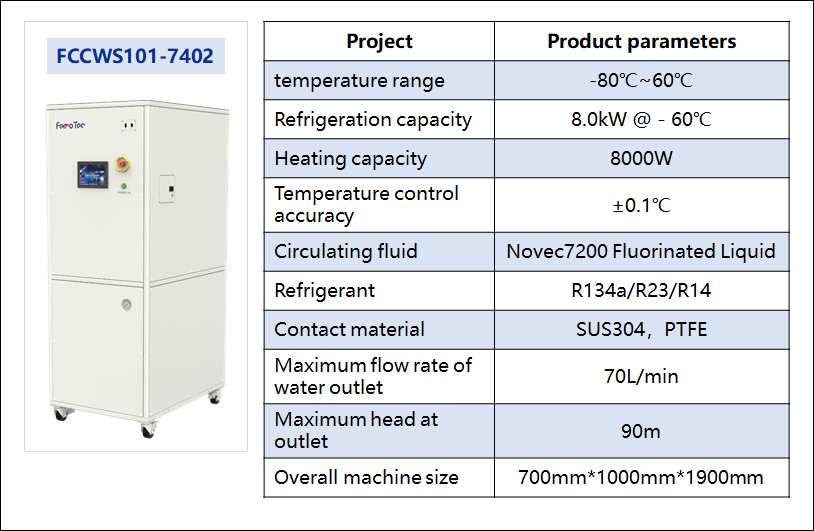

(III) Introduction of FerroTec semiconductor temperature control products

FerroTec is a top company in the semiconductor industry. Its independently developed and designed FCCWS101-7402 is an ultra-low temperature compressor temperature control device with a cooling capacity of 8.0kW@-60℃ and a heating capacity of 8000W. It achieves precise temperature control through PID algorithm and is equipped with an intelligent temperature control system, which can realize real-time dynamic temperature adjustment, support remote communication, and realize real-time fault warning to ensure safe and stable operation of the equipment.

Ultimate cooling capacity

The cascade compression system and hybrid refrigeration technology are used to break through the limits of traditional refrigeration. The temperature range can cover -80°C to 60°C, meeting stringent requirements such as rapid cooling of semiconductor wafers and testing of superconducting materials.

Excellent temperature control

Integrating high-precision PID algorithm and advanced sensing technology, it can maintain stability of ±0.1°C in the ultra-low temperature range, ensuring the repeatability of experiments and processes.

Energy-efficient design

The expansion valve opening is automatically adjusted through PID to achieve rapid temperature rise and fall, significantly reducing energy consumption compared to traditional refrigeration solutions, and has significant long-term cost advantages, making it particularly suitable for industrial scenarios with long-term continuous operation.

Extreme environment reliability

In response to the 24/7 operation requirements of semiconductor equipment (such as ion implanters), special low-temperature alloy materials and modular antifreeze design are used. Key components can withstand extreme environments of -150°C and are equipped with multiple safety protection mechanisms to ensure stable operation of the equipment under long-term high loads.

In the future, as China's manufacturing industry continues to upgrade, FerroTec will continue to deepen its localization strategy, increase technological innovation, improve its supply chain system, enhance product quality, and expand its global market. Through digital transformation and green development, FerroTec will strive to become a global leader in temperature control and contribute to the high-quality development of China's manufacturing industry.