Chiller Science Class | It turns out that the compressor chiller can be so categorized!

Welcome to Chiller science mini class! Generally speaking, compressor-type chiller can be categorized in different dimensions according to the conditions of cooling method, working temperature, precision level and number of channels. This issue of small cool will be on the cooling method and working temperature two basic classification criteria for its classification and introduction. If you have any questions about the content of the article, or want to know more about water chillers, welcome to leave a message in the comments section~!

01 Compressor chiller: classification according to cooling method

Compressor chiller is an important equipment in industrial refrigeration system, widely used in plastic molding, food processing, pharmaceutical, chemical and other fields. According to the different cooling methods, compressor-type chiller can be divided into air-cooled chiller and water-cooled chiller, the following take a look at the difference between these two types of chiller.

01 Air-cooled chiller:

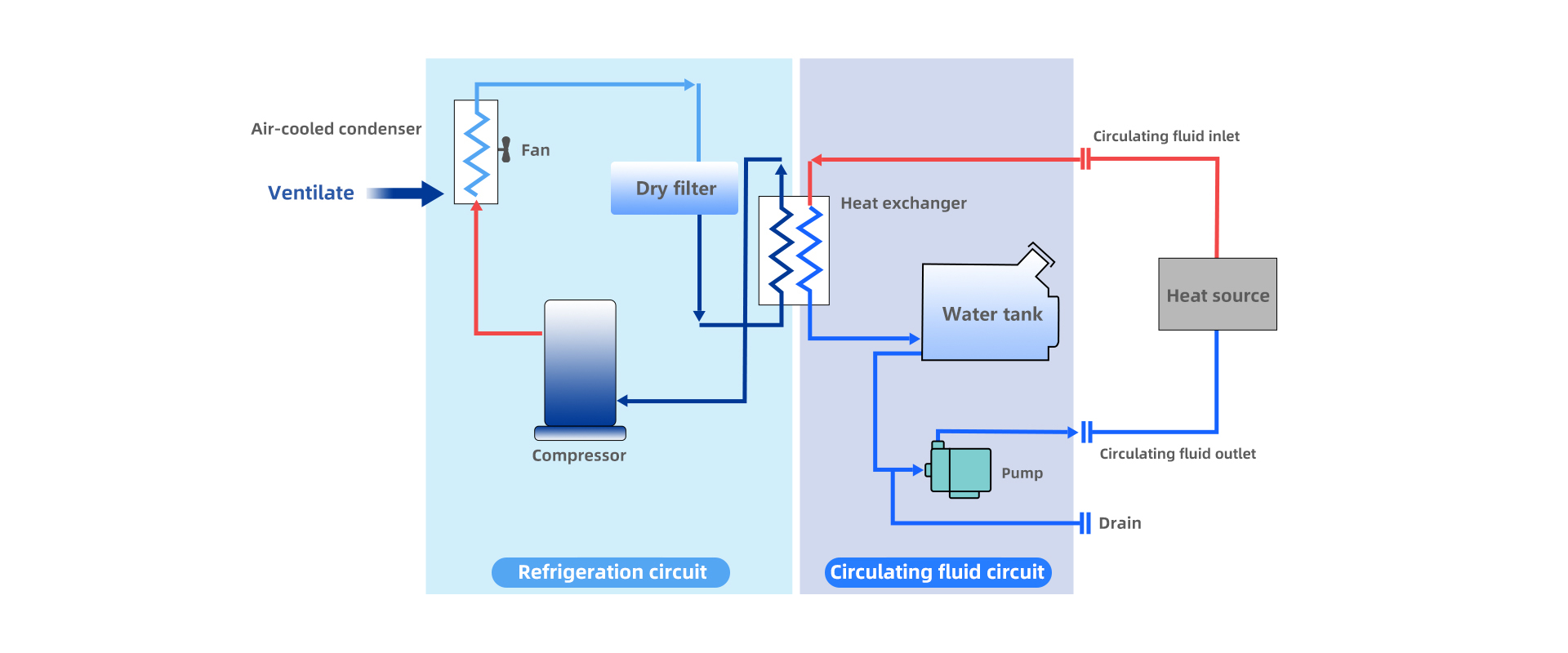

Air-cooled chillers take away heat by fan-driven air. Its advantage is that it does not need to be equipped with a plumbing system and has high installation flexibility. However, in a high temperature environment, the heat dissipation effect will be affected, and the fan will produce a certain noise during operation. Therefore, this system is commonly used in small-scale industrial production and places that do not require high ambient noise.

Air-cooled chiller working principle diagram

02 Water-cooled chillers:

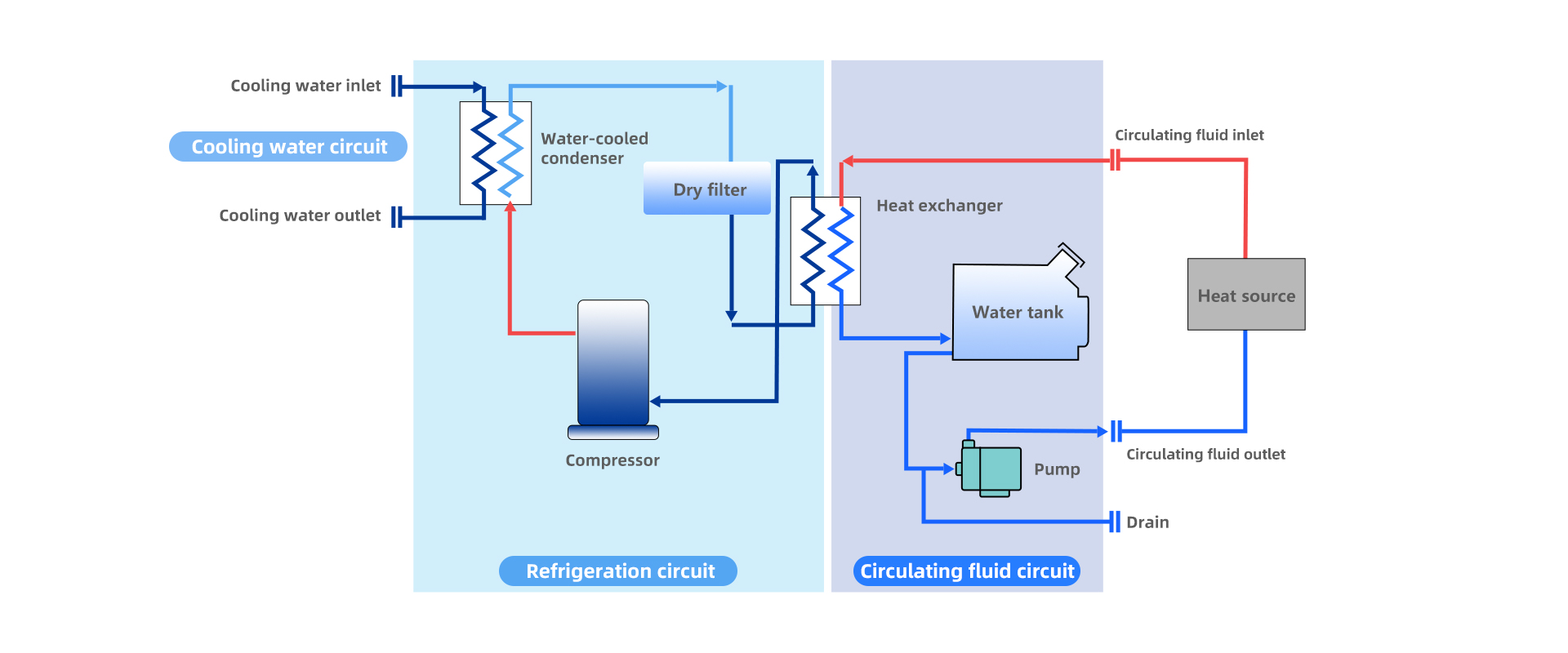

Water-cooled chillers rely on water circulation for heat dissipation and need to be equipped with a corresponding water piping system. This system has a high cooling efficiency, can provide a larger cooling capacity, and has a strong adaptability to the ambient temperature, and can operate efficiently in high-temperature places. Therefore, this system is commonly used in large-scale industrial fields and places that require high cooling capacity and high ambient temperatures.

Water-cooled chiller working principle diagram

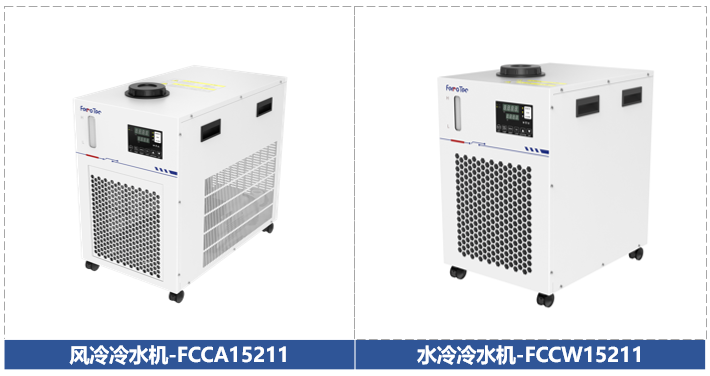

At present, FerroTec thermoelectric business can meet the needs of customers in different industries for air-cooled and water-cooled compressor chiller models. The following picture is a real model case, if you need welcome to call us for advice: 15967138668

02 Compressor-type chiller: classification according to the working temperature

In addition to the cooling method, we can also be classified according to the operating temperature of the compressor-type chiller: first of all, 0 ℃ as the demarcation point can be divided into room temperature and low-temperature chiller. Low-temperature chiller can be divided into two-stage compression refrigeration and compound stack refrigeration chiller according to different refrigeration principles. When we need to get the low temperature above -60℃, we can use two-stage compression refrigeration cycle; and when we get the low temperature below -60℃, we must use compound stack refrigeration cycle. Here are the working principle and detailed introduction of these types of chillers.

01 Room temperature type chiller:

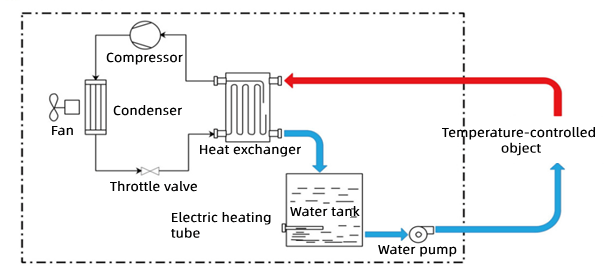

Normal temperature type chiller is usually applied to the working environment above 0℃. It mainly uses the change of refrigerant state to realize the heat transfer (see chiller science classroom No. 1). Compared with low-temperature chillers, room-temperature chillers have significant cost advantages; they can meet most cooling occasions that do not require deep refrigeration, such as food storage and transportation of some medical supplies. It has a wider range of applications and higher safety.

Normal temperature chiller system schematic diagram

02 Low temperature type - two-stage compression chiller:

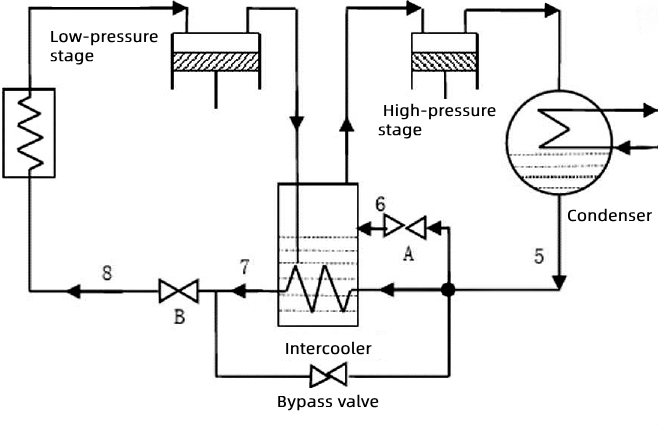

Two-stage compression chiller goes to compress the same refrigerant through two compressors of different pressure levels, so as to gradually raise the pressure and lower the temperature, and gradually realize deep refrigeration. The refrigerant gas is first compressed in the low-pressure stage compressor, cooled by the intercooler, and then entered the high-pressure stage compressor for further compression. The cost of this system is lower than that of the compounded refrigeration system, but its low-temperature limit is limited, and it is generally used in places above -60℃.

Schematic diagram of one-stage throttling intermediate incomplete cooling cycle system

03 Low-temperature type-compound chiller:

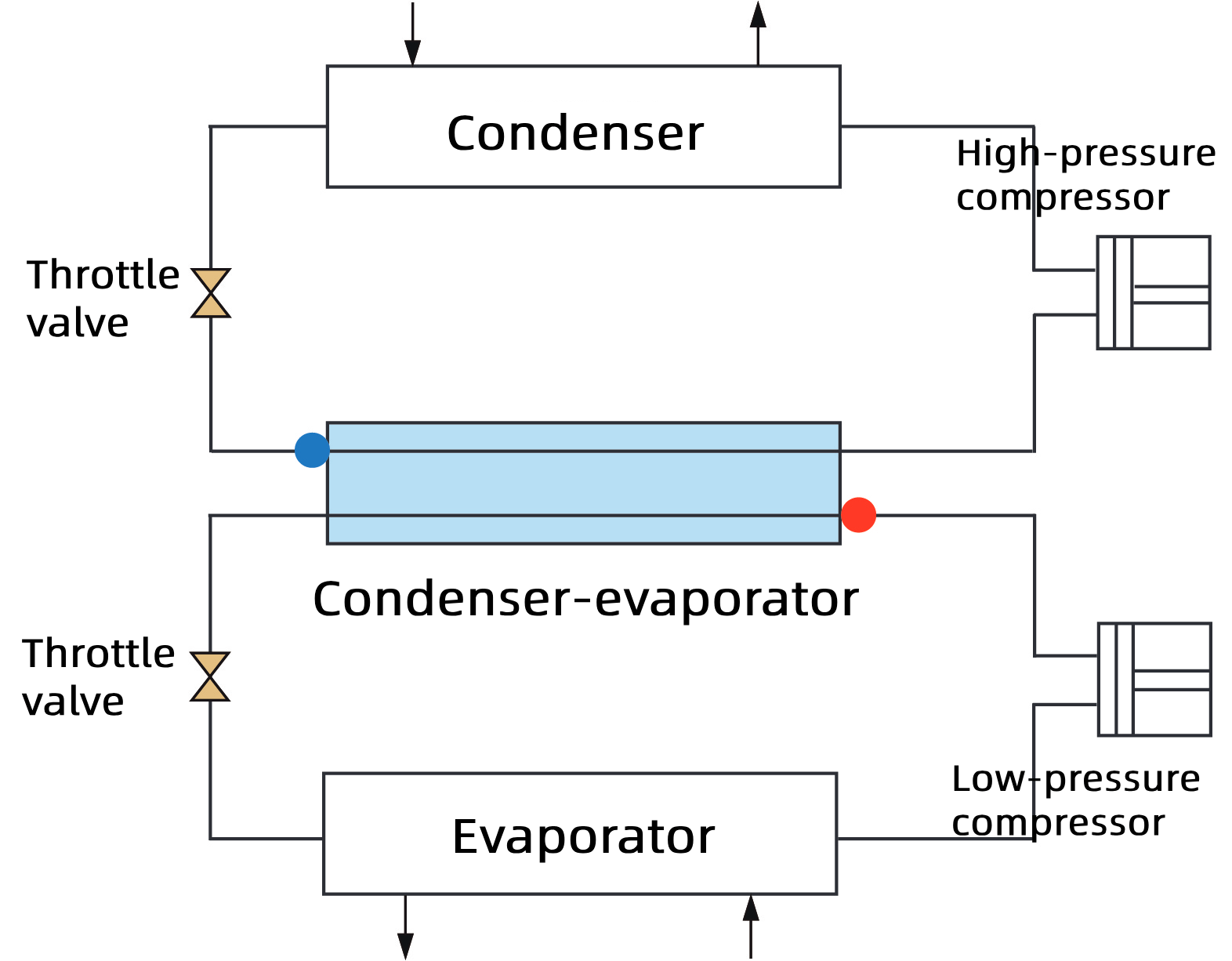

If you want to get -60 ℃ below the low temperature, using a single refrigerant multi-stage compression has been difficult to realize, at this time we can use the cascade refrigeration system. Compound chiller using a number of different refrigeration circulatory system “relay”, through the high-temperature stage and low-temperature stage system to work together to achieve low-temperature effect. Compound refrigeration system is relatively simple and reliable, at the same time, the system is adaptable, can be adjusted through the number of stages or refrigerant to match the different temperature requirements. The split-pressure design of the system reduces compression ratio limitations and extends equipment life.

Schematic diagram of a compound refrigeration cycle system

At present FerroTec thermoelectric business to meet the needs of customers in different industries on the room temperature type and low temperature type two-stage compression chiller this two types of chiller models. The following picture is a real model case, if you need welcome to call to consult: 15967138668

Next notice

Through today's lesson, I believe you have a deeper understanding of the classification of compressor-type chiller. In the next issue, small cool will further introduce the low-temperature type of compressor-type chiller - compound chiller, please look forward to it!