Ensuring chip performance: Applications and advantages of FerroTec chillers in FT testing

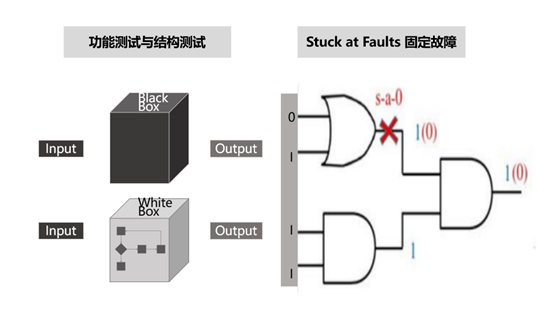

01 Principle of FT testing

The principle of FT testing is to install the chip in a real or simulated application environment, and apply the input signal and detect the output signal through the test equipment (such as test machine Tester and sorting machine Handler) to judge whether the chip function and performance meet the design requirements. The Tester is used to generate test vectors and analyze the response of the chip, while the Handler is responsible for automatically picking up the chip under test and placing it in the test position of the tester.

During the test, the test machine sends specific test patterns and signals by connecting with the pin of the chip, and monitors the response of the chip. By comparing the expected output with the actual output, you can determine whether the chip meets the specifications. If the chip fails the test, it will be flagged and removed from the production line to prevent substandard products from entering the market.

FT testing is a key link in ensuring the quality and performance of semiconductor products. Through rigorous testing at different production stages, defects can be found and eliminated, processes can be optimized, yields can be increased and costs reduced.

02 FT measuring instrument

FT testing (finished product testing) the main practical instruments are Tester and three-temperature sorting machine (Handler) plus high and low temperature Chiller (Chiller) :

Sorting machine: The main function is to automatically pick up the chip to be tested by the mechanical arm, place the chip to be tested to the test station, and connect the pin of the chip to the function module of the test machine through the base on the test station and the exclusive connection line.

Chiller: mainly provides high temperature (80~180 ° C), medium temperature (20~80 ° C), low temperature (-55 ° C ~20 ° C) for the sorting machine, and provides the corresponding high and low temperature environment required for the chip under test. Through the high and low temperature environment provided by the chiller, the ambient temperature of the chip in real use is simulated, and the actual performance and stability of the chip in different environments are tested.

Test machine: the input signal is applied to the chip and the output signal is collected to determine whether the function and performance of the chip meet the requirements of the design specification under different working conditions.

03 FerroTec tests special chiller equipment

Ferrotec Group (China), as an internationally renowned supplier of semiconductor products and solutions, introduces and absorbs advanced production technologies, and develops high-performance chiller products suitable for the Chinese market. Our products have significant advantages in the fields of gluing, developing, etching, film deposition, cleaning, testing and laser. Among them, FT test special chiller equipment - high and low temperature chiller, this series of products can achieve the following functions:

Efficient refrigeration: Accurate temperature control can be achieved in the range of -80 ° C ~200 ° C, and 7,000W cooling capacity can be achieved at -70 ° C.

Precise temperature control and stable operation: through PID program, the temperature stability of the equipment circulating liquid fluctuates within ±0.1℃, promoting the reliable operation of the process. Users can set the temperature range, working time and other parameters according to the actual needs, and the system can automatically adjust the working state to ensure that the equipment runs in the best state.